Trident – Thermal Conductivity Instrument

Inquire productThe Trident enables thermal conductivity testing of a wide range of solids, liquids, powders and pastes and offers maximum versatility by combining the modified transient surface swelling method (MTPS), the transient surface swelling method (TPS) and the transient line swelling method (TLS) in one modular system.

The MTPS high precision method is the simplest and most versatile. The TLS Needle method provides maximum robustness for those sticky situations. The Flex TPS method provides the greatest flexibility over experimental parameters with C-Therm’s flex sensors. Learn more about how each method works below.

3 methods for thermal conductivity:

- MTPS

- TLS Needle

- Flex TPS

Modified Transient Plane Source (MTPS)

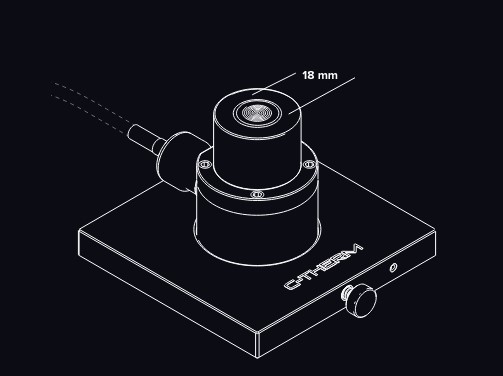

Simple and Precise. The MTPS method employs a single-sided sensor to directly measure thermal conductivity and effusivity of materials. The MTPS method has the highest precision, highest sensitivity, shortest test time, and is the easiest to use among all three techniques.

Transient Line Source (TLS) Needle

The TLS method employs a needle probe to characterize the thermal conductivity of viscous and granular materials. It is the most robust sensor for thermal conductivity testing.

Transient Plane Source (TPS) Flex

The TPS method employs a double-sided hot disc sensor to simultaneously determine thermal conductivity, thermal diffusivity and specific heat capacity of materials from a single measurement. TPS provides the user the greatest flexibility and control over experimental parameters and avoids the use of any contact agents. Recommended for more experienced users.

- Specifications

-

Test Methods MTPS TLS Needle Flex TPS Recommended applications Aerogels, Automotive, Batteries, Composites, Insulation, Explosives, Geological, Liquids, Metals, Nanomaterials, Metal Hydrides, Nuclear, Phase Change Materials (PCMs), Polymers, Rubber, Thermal Interface Materials (TIMs), Thermoelectric Polymer Melts, Semi-Solids, & Soil. (Not suitable for lower viscosity fluids due to convection.) Cement/Concrete, Metal Sheets, Polymers, Porous Ceramics, & Thin Films Thermal Conductivity Range 0 to 500 W/mK 0.1 to 6 W/mK 0.005 to 2000 W/mK Thermal Diffusivity Range 0 to 300 mm²/s* Not applicable up to 1200 mm²/s Heat Capacity Range Up to 5 MJ/m³K* Not applicable Up to 5 MJ/m³K Thermal Effusivity Range 5 to 40,000 Ws½/m²K Not applicable Not applicable Temperature Range -50º to 200ºC -With option to extend to 500ºC -55º to 180ºC -With option to extend to 300ºC -50º to 300ºC Precision Better than 1% Better than 3% Better than 2% Accuracy Better than 5% Stated for °20C ± (3% + 0.02) W/mK Better than 5% Test Time 0.8 to 3 seconds 1 to 4 minutes 10 to 180 seconds Sensor Size 18 mm diameter 150 mm length 6 mm, 13 mm and 30 mm diameter sensors available Minimum Sample Size Solids: Min. diameter of 18 mm Min. thickness is dependent on the thermal conductivity. For materials under 1 W/mK a min. thickness of 1 mm is suggested. Liquids & Powders: 1.25 mL 80 mL Requires two identical samples. The diameter of the samples should be 2.5X sensor diameter (e.g. 6 mm sensor requires sample diameter of 15 mm) Thickness should be at minimum the same diameter as the sensor (e.g. 6 mm sensor requires 6 mm thick samples. Maximum Sample Size Unlimited Unlimited Unlimited International Standards ASTM D7984 ASTM D5334, D5930, and IEEE 442-1981 ISO 22007-2, GB/T 32064 *calculated - Applications

-

- Polymers

- Nanomaterials

- Heat Transfer Fluids

- Geological

- Phase Change Materials

- Insulation

- Automotive&Electric Vehicles (EV)

- Building Materials

- Metals

- Thermal Interface Materials

- Oil-Gas

- Powders

- Accessories

-

Controlling environmental factors during testing is critical to gaining meaningful, repeatable and comparable thermal conductivity results. With C-Therm’s line of accessories, precise control of temperature, compression, pressure and humidity is possible – with a wide range of accessories available.

- Download

Let's get to know each other

Would you like to purchase one of our products, do you have any question about a product or about services or do you need further information?

We are always just one phone call away or you can send us a message here